06.2024 Flexball made of DIPRO®flex S, Filament Printing

Softness is a combination of Shore hardness and geometry.

As the hardness of the filaments has a limit, it makes sense to make the application soft by using the appropriate geometry.

The Flexball is printed from filament with Product ID 1634, PX-DIPRO®flex S90.1H2/1300*700F with 90 Shore A.

Due to its geometry, the ball is highly flexible despite its relatively high hardness.

Special features:

- super layer adhesion

- temperature limit 120 °C

- all colors are possible

- no pre-drying of the filaments

- good hydrolysis resistance

- hard/soft bonds are possible with DIPRO®blend H

- good recyclability with all polyolefins

- low density

Forget the problem of “wet filaments”, as is the case with TPU.

DIPRO®flex H with higher strength and good abrasion resistance are available.

Source: GRAUTS

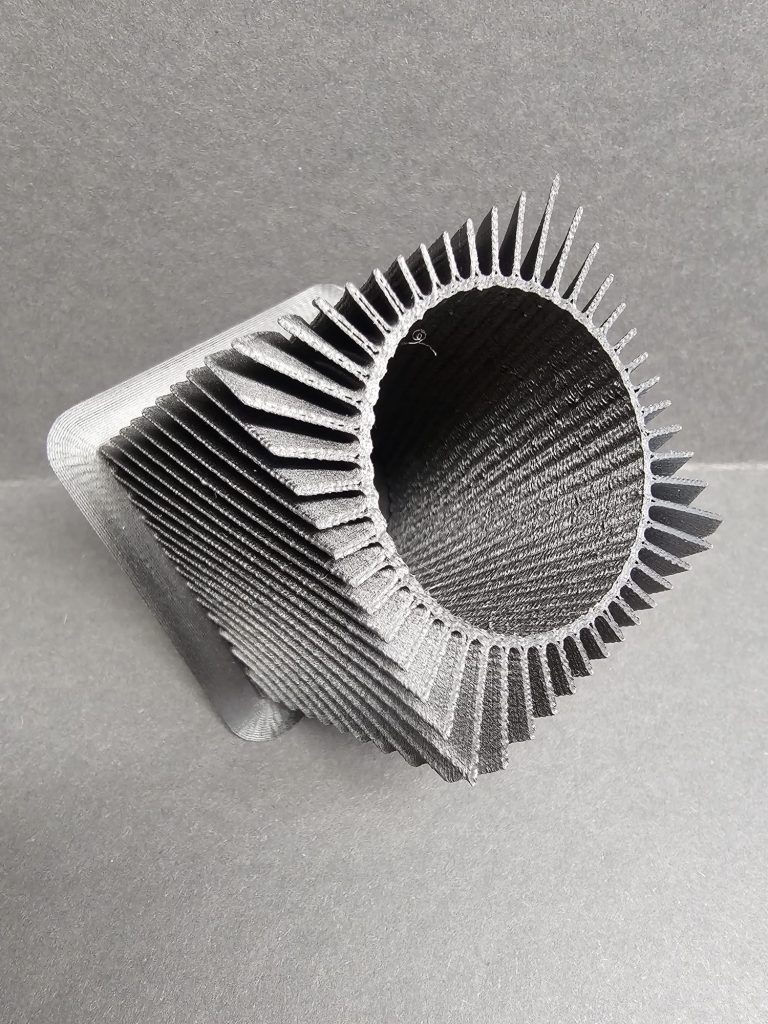

06.2024 Stiff Ball Lattice Structure and Turbine Wheel with DIPRO®blend H, GF 25 %

All examples show the very good molding of delicate structures and complex geometries.

All applications are made of Product ID 2008, PX-DIPRO®blend H3GF5H4Z24*800F, a HIGH-PERFORMANCE-POLYOLEFIN with 25 % special glass fiber reinforcement.

Special features:

- very low shrinkage

- high heat resistance

- high rigidity

- low warpage

- good building plate adhesion

- UV stabilization even for light colors

- high strength across the fiber

- high impact strength, even notched and at low temperatures (CHARPY k > 25 kJ/m²)

- all colors are possible

- suitable for hard/soft combinations in filament pellet printing

Shaping is almost unlimited in filament (FFF/FDM) and pellet printing (FGM/FGF).

Ultra-tough grades are available (CHARPY k >30 kJ/m²).

Source: GRAUTS

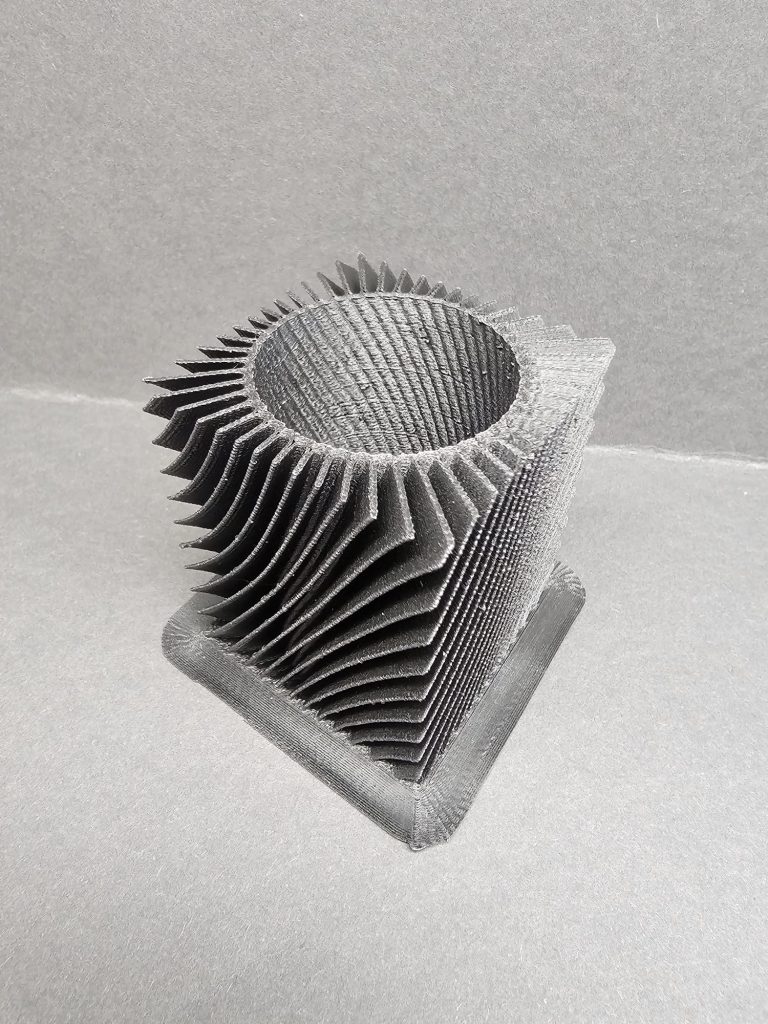

06.2024 Hopper for 3D Pellet Printers – Precision Polyamide with 25 % Special Glass Fiber Reinforcement

To improve the flowability of pellets, especially Thermoplastic Elastomers, we have replaced the original asymmetrical hopper with a symmetrical axial hopper.

Source: DIPROmat

Product ID 1610, PX-DIPRO®mid T25.8CH2GF5*9200F

Precision polyamide with 25 % special glass fiber reinforcement

Special features:

- very low processing shrinkage

- high heat resistance

- high strength and rigidity

- little influence of water absorption on strength

- high strength across the fiber

- good building plate adhesion

Simply print your machine components yourself!

Source: DIPROmat

05.2024 DIPRO®flex Thermoplastic Elastomers

DIPRO®mat presents a complete series of Thermoplastic Elastomers with the following special features

- TPE masterbatch for producing your own recipes on the injection molding machine

- low-compression set grades starting at 3 ShA

- haptic-optimized, filled and unfilled, high and ultra-high molecular weight TPS elastomers

- damping polymers for protective clothing (protectors) and vibration damping

- bonding grades for PA, PPB, PC, PC-ABS, ABS

- extrusion grades in the Shore A/D range for hoses and flexible pipes

- completely new hard/soft combinations with DIPRO®blend H

- DIPRO®flex for 3D printing, also for printed hard/soft combinations

Source: DIPROmat

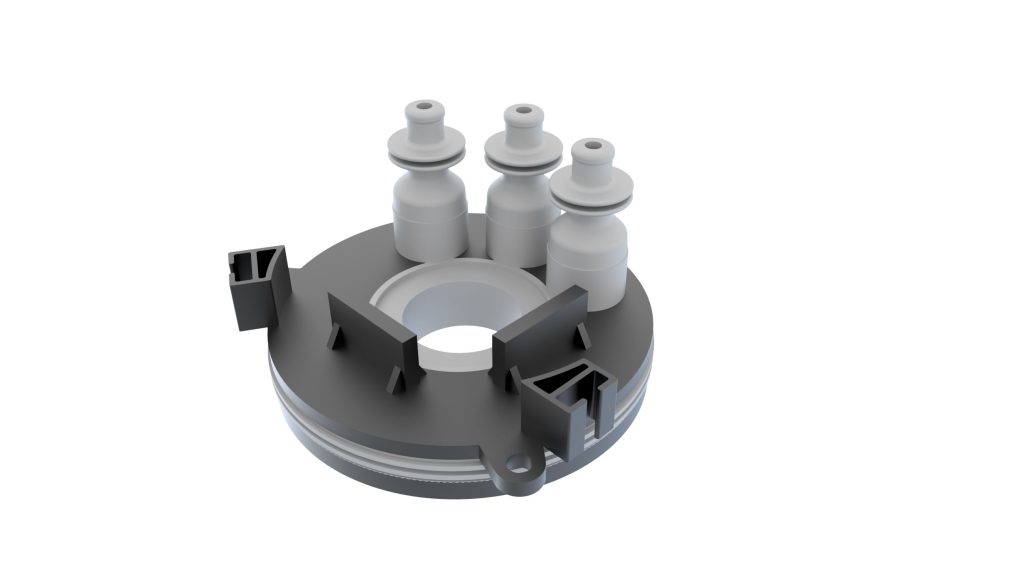

Seal carrier with cable grommets

Cable grommets (natural/light):

DIPRO®flex S Thermoplastic Elastomer, 50 ShA, with polyamide adhesion

Product ID 1173, PX-DIPRO®flex S50H23B2/1230*702/0201

Housing component (black):

PA 30 % GF

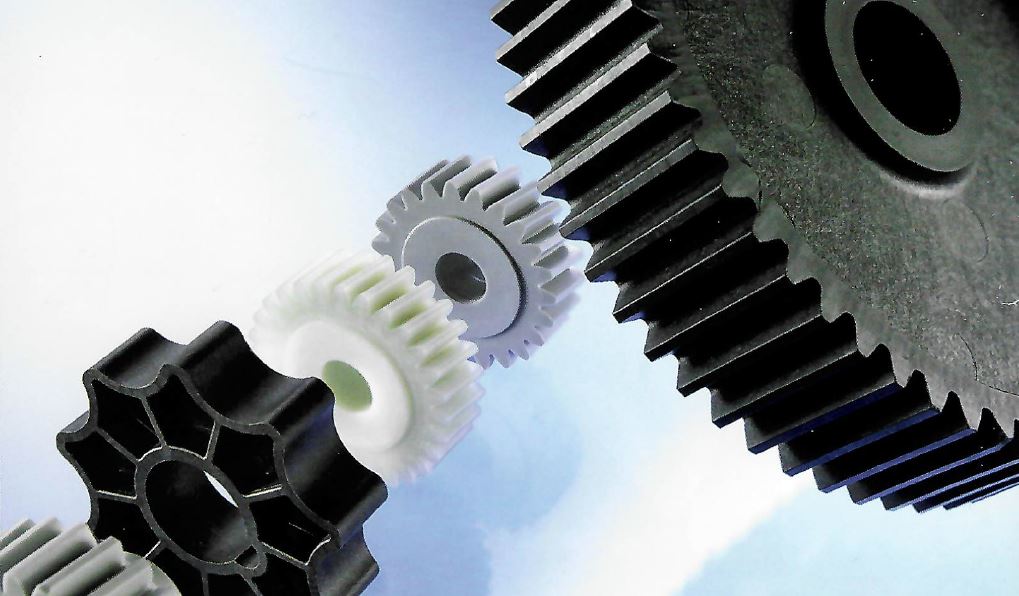

04.2024 Radiation-Crosslinkable Polymers for Injection Molding and Extrusion

Properties after radiation-crosslinking

- no longer meltable after crosslinking with E-Beam

- reduced creep behavior under load

- increased Tg (glass transition temperature) to >100 °C

- reduced abrasion for bearings and gears

- radiation cross-linked parts have a memory effect

- improved chemical resistance

- lower water absorption

- higher surface hardness

Source: DIPROmat / BGS

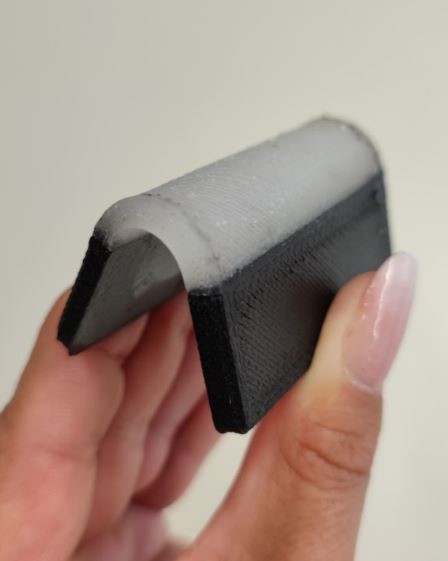

04.2024 Hard/Soft Connection, FFF/FDM Printing

Source: DIPROmat

Housing with seal

Housing component (black):

High-Performance Polyolefin, ultra-tough, 25 % GF

Product ID 1492, DIPRO®blend H3GF5H1Z34*9200F

Sealing component (red):

Thermoplastic Elastomer, 80 Sh A

Product ID 1597, DIPRO®flex S80H2/1300*702F

03.2024 Super Surface with DIPRO®blend H GF 15 % – Filament Printing

Source: DIPROmat

Product ID 1443, DIPRO®blend H3GF3H1Z44*9200F – housing material for very robust applications

- low molding shrinkage

- little warpage

- ultra-tough despite 15 % glass fiber reinforcement

- heat deflection temperature HDT / B = 134 °C

- processing without pre-drying

11.2023 Hard/Soft Combination, FDM Printing

Hard/soft combinations with co-recyclable products can now also be printed using the FDM/FFF or pellet printing process!

A very valuable feature, especially with filament printing, is that the spools do not have to be pre-dried.

These hard/soft combinations are also easy to produce in larger quantities using injection molding.

Source: GRAUTS

Garden chair or appliance base

- Black: DIPRO®blend H GF 25 %

- Blue: DIPRO®flex S90

11.2023 DIPRO®blend H 20 % Mineral MT

Source: DIPROmat

Product ID 1832, DIPRO®blend H3MT4H1Z24*800F

- super surface

- isotropic shrinkage

- impact resistant

- can be colored as desired

11.2023 ARBURG-FORMNEXT Presentation / DIPRO®mid on FREEFORMER

Bicycle tire lever made of DIPRO®mid H GF 25 % for changing bicycle tires

- low-warpage precision polyamide

- little influence of moisture on part properties

- high strength

- high rigidity

- easily transferable to injection molding

10.2023 DIPRO®blend H with and without Glass Fiber Reinforcement / Filament Pressure

Housing, medium stiffness, ultra-tough

- very good layer adhesion

- low mold shrinkage

- easy to process without drying

- low density

- no stress crack sensitivity

- acid and alkali resistant

Lid, 25 % GF reinforcement

- high stiffness Et = 4.500 Mpa

- low warpage for high precision parts

- high strength pmd

09.2023 Whether Flower Vase, Car Bumper or Technical Housing – Everything 3D Printed!

We like to use these vases to evaluate printability, layer adhesion and haptics. Shown here with a wall thickness of only 0.4 mm.

All polymers shown in these 3 vases look similar, but differ significantly from each other.

1) Vase large

– Product ID 1633, PX-DIPRO®blend H3.1H1Z64700F, or Product ID 1864, PX-DIPRO®blend H3H2Z14601EX –

Depending on the stiffness requirement, this demonstrator was made of DIPRO®blend H product ID 1633, PX-DIPRO®blend H3.1H1Z64*700F, or product ID 1864, PX-DIPROblend H3H2Z14*601EX. These two unreinforced and ultra-tough polymers have an Et Modulus of 856 MPa to 1,050 MPa and are virtually indestructible due to ultra-tough impact and notched impact properties.

2) Vase center

– Product ID 1832, PX-DIPRO®blend H3MT4H1Z24*800F –

In order to further increase the stiffness, 20 % mineral type “MT” was used for product ID 1832, PX-DIPRO®blend H3MT4H1Z24*800F. Now a housing material with Et Modulus of 1,520 MPa is available with high impact strength and still good notched impact strength. The surface finish is excellent.

3) Vase on the right

– Product ID 1831, PX-DIPRO®blend H3MTGF42H1Z24*800F –

For some housings, the above-mentioned stiffness is not yet sufficient, which is why Product ID 1831, PX-DIPRO®blend H3MTGF42H1Z24*800F, was developed as a housing grade with 20% mineral type “MT” and 10% special glass fiber for low-cost housing materials. The Et Modulus is now 3,030 MPa.

In addition to this group of polymers, 10 – 25% specialty glass fiber polymers are available up to 4,500 MPa tensile modulus.

09.2023 DIPRO®flex S90.1H2/1300*700F, Product ID 1634 – Thermoplastic Elastomer for Filament Printing up to 120 °C (HSBC)

Ultra-high molecular weight TPS for highest demands

- hardness 91 ShA / 32 ShD

- 30 % lighter than TPU

- extremely good layer adhesion

- application temperature up to 120 °C

- no polymer degradation due to moisture

- no predrying of the filament spool

- hard/soft combinations possible with DIPRO®blend-H

- easy to recycle with all polyolefins

- all colors are possible

- UV-resistant

- hydrolysis, acid and alkali resistant

- non-slip surface

- elongation at break md/pmd = 600%/ 800%

08.2023 Market Launch of DIPRO®blend H3.1H1Z64*700F, Product ID 1633 – an ULTRA-TOUGH HOUSING MATERIAL!

High-Performance Polyolefin, unreinforced, for filament and pellet printers

- Et Modulus = 856 Mpa

- tensile strength at break = 30 Mpa

- Charpy k = 87

- Charpy = N.B.

- elongation at break = 500 %

- VICAT, 10 N = 108 °C

- no pre-drying of pellets and spools

These are the facts for an almost indestructible housing material of medium stiffness for robust applications.

The part shown has 0.4 mm wall thickness and demonstrates the extreme flexibility and toughness.

An ideal material for automotive parts, power tool industry, and sports and leisure applications.

Stiffer and softer DIPRO®blend H grades are available.

08.2023 DIPRO®blend H High-Performance Polyolefin 15 % GF (Special Glass Fiber Reinforcement), Ultra-Tough

Source: DIPROmat

Car storage tray for cell phone, cables and more

This material was chosen for automotive interior applications for the following reasons:

- medium stiffness

- extreme high notched impact strength

- heat deflection temperature HDT-B of 134 °C

- good heat aging behavior

- low material density of 1.01 g/cm³

- low part density due to INFILL of 0.75 g/cm³

- easy to print

- no pre-drying of the filament spool

- high absorption, no tendency to rattle

- matt black surface

07.2023 DIPRO®mid C Precision Polyamide with 15 % Carbon Fiber Establishes Itself

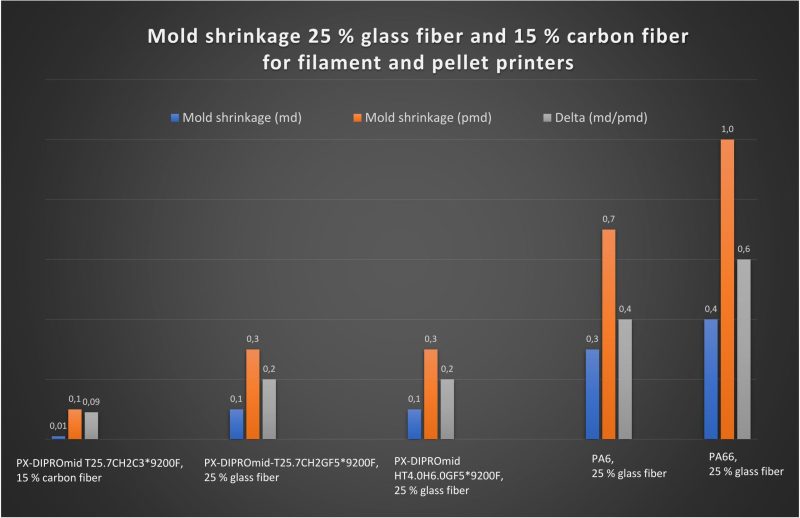

Minimal mold shrinkage (0.1%/0.1% – MD/PMD), high strength (153 /147 MPa – dry/conditioned), stiffness (11,100 / 9,700 MPa – dry/conditioned) and heat deflection temperature (HDT-B=200 °C) with simultaneous ESD (Electrostatic Discharge) properties enable forward-looking applications in FDM/FFF 3D printing.

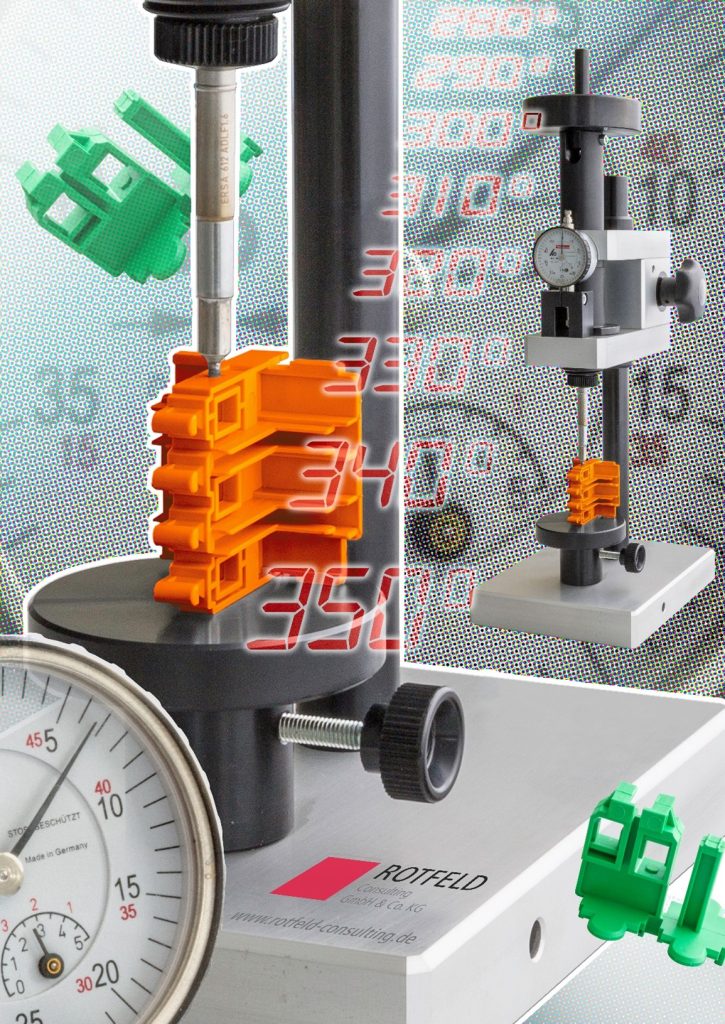

01.2023 DIPRO®blend H and DIPRO®flex High-Performance Polyolefins with Minimal Mold Shrinkage for High Precision

Together with ROTFELD-Consulting, DIPRO®mat has been able to develop a range of unreinforced and special glass fiber-reinforced high-performance polyolefins (patent pending) that exhibit hardly any shrinkage, are incredibly tough and – unlike conventional impact-modified PPs – do not lose any heat distortion temperature, since a blend component provides a Tg (glass transition temperature) of 160°C.

This results in polyolefin compounds with high precision available for injection molding and 3D printing. An exciting fact is that the development started in additive manufacturing, where a large warpage is useless, and now returned to injection molding applications.

12.2022 First Processing with Adaptive IR Zone Heating System (FFF/FDM Printing)

The equally smooth surface coupled with high strength in the build-up direction was achieved with Apium’s patented IR zone heating system. In this process, only the uppermost layers are melted so that there is a high level of layer bonding. In the meantime, the lower layers can cool down without any further thermal influence on the surface quality.

Printer: APIUM Filament Printer

Filament: APIUM

Material: DIPRO®mid Carbon

11.2022 First Production with DIPRO®mid Carbon Fiber on High-Speed Pellet Printer

Source: GRAUTS

Machine operating lever

- Printing speed up to 600mm/s

10.2022 Filament / Pellet Printing – Hard/Soft Compound 3D

Simple hard/soft compound

- made on Tumaker 3D printer (filament and pellets)

- Hard: Filament printing / Material: DIPRO®blend GF 15 %

- Soft: Pellet print / Material: DIPRO®flex S60H24

- available as of 1st quarter 2023

09.2022 Development of PRECISION Polyamide for Flame Retardant (Injection Molding and 3D Printing) & Halogen-free DIPRO®flex FR, 75 ShA and Above.

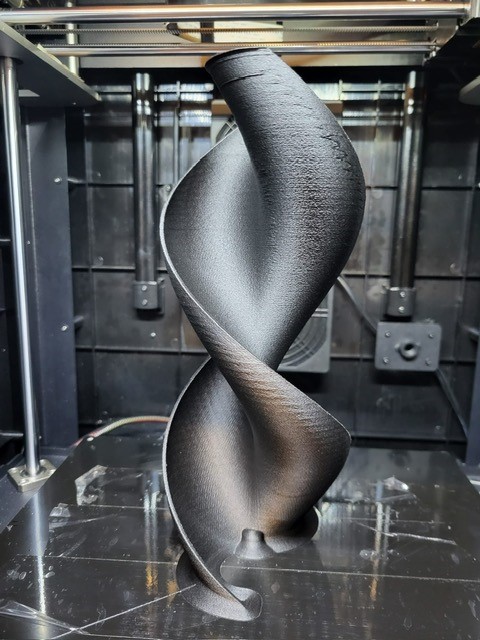

08.2022 Flexible Structure Made of DIPRO®flex for Pellet and Filament Printing, up to 120 °C, Flexible, Super Bonding Strength for Flexible Three-Dimensional Structures

Source: GRAUTS

Flex structure

filament print from DIPRO®flex, 90 ShA

- good reset behavior

- temperature up to 120 °C

- can be colored as desired

- no pre-drying necessary

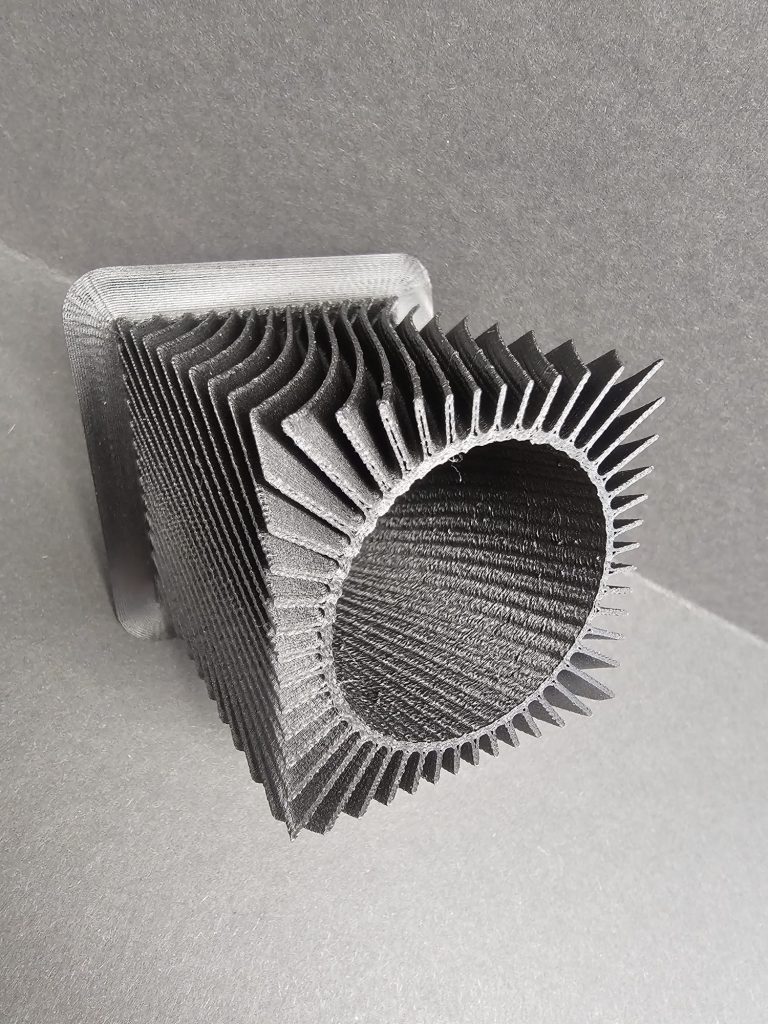

07.2022 Filaments by Network Partners with CARBON and GLAS Fiber Reinforcement with Extremely Low Shrinkage

Source: GRAUTS

Cooling nozzle

filament print made of DIPRO®mid 25 % GF

Source: GRAUTS

Sports bike bottle holder

filament print from DIPRO®mid 15 % CF

Source: GRAUTS

Turbine wheel

filament print made of DIPRO®mid 15 % GF

06.2022 TPE Masterbatch Development for In-House Production of TPS with Low Compression Set for Injection Molders & Printable TPE Special Compounds for FFF/FDM/LAAM/VLAAM and Pellet Printers

Source: Q.Big 3D

DIPRO®flex pellet printing

05.2022 DIPRO®mid for High-Capacity Pellet Printers VLAAM

Caravan rear end

Precision polyamides with minimal mold shrinkage for high-capacity printers

- DIPRO®mid 25 % GF

- Caravan rear end

- Largest molded part printed to date

- Dimension: 210 x 70 x 30 cm

- Co-Founder Q.BIG 3D, Dennis Herrmann

01.2022 Development of Radiation-Crosslinkable DIPRO®mid PRECISION Polyamides for DIPRO®mat

Source: DIPROmat

Crosslink tester with switching bridge

Radiation-crosslinkable DIPRO®mid precision polyamides show the following differences compared to conventional PA grades:

- little warping due to low shrinkage

- very good surface

- low influence of air humidity on properties

- thermostable crosslinking additive, homogeneously compounded, up to 40 %

- energy efficient due to 35 °C – 40 °C lower melt temperature than PA66

- maximum 60 % glass fiber reinforcement possible

08.2021 Product Highlights ETP for Filament and Pellet Printing

Reinforced high-performance PA grades for FFF (filament printers) and FGM (pellet printers)

All FFF-FGM polyamides with glass fiber reinforcement show extremely low mold shrinkage. This is particularly important for large-format printers.

PX-DIPROmid T25.7CH2C3*9200F Product-ID: 912 Request data sheet

(semi-aromatic, 15 % carbon fiber, HDT/B=200 °C)

PX-DIPROmid-T25.7CH2GF5*9200F Product-ID: 910 Request data sheet

(semi-aromatic, 25 % glass fiber, HDT/B = 200 °C)

PX-DIPROmid HT4.0H6.0GF5*9200F Product-ID: 921 Request data sheet

(PPA-25 % glass fiber, low warpage, Tg = 125 °C, HDT/A 215 °C, HDT/B 243 °C)

07.2021 Product Highlights ETP Injection Molding

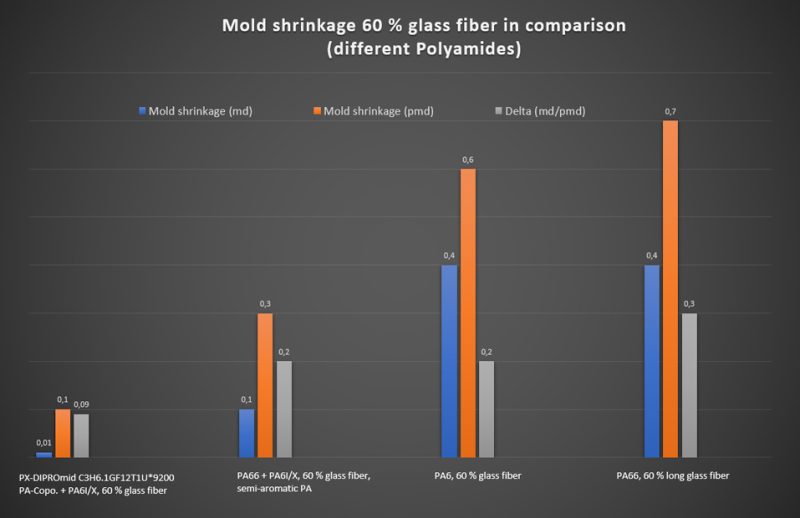

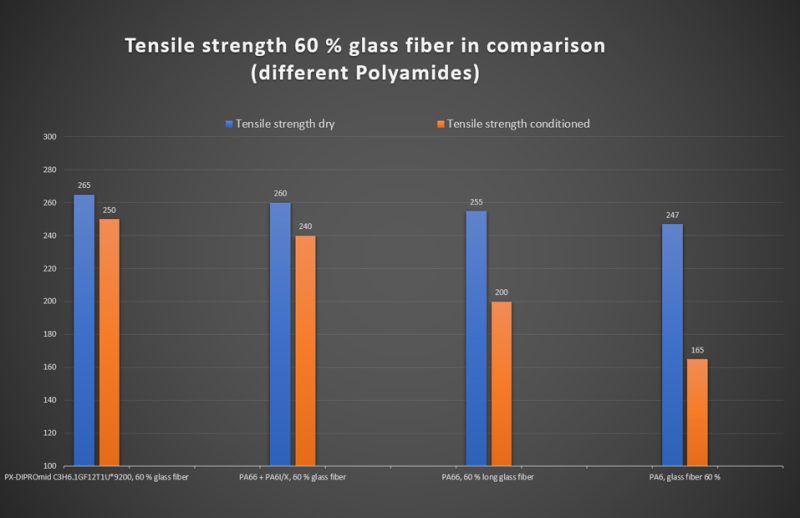

High stiffness low warpage polyamides (40-60 % glass fiber reinforcement) with aesthetic surface, low warpage

PX-DIPROmid A1H6.1G12T3U*9200 Product-ID: 807 Request data sheet

PA66 + X, 60 % glass fiber, ultra-flow, 3rd generation partially aromatic PA, extremely good surface, low warpage.

The influence of moisture absorption on the properties is low. This is a typical metal substitute material with aesthetic surface.

PX-DIPROmid C3H6.1GF12T1U*9200 Produkt-ID: 793 Request data sheet

PA-Copo + X, 62 % glass fiber, partially aromatic, a possible answer to constantly recurring PA66 shortages.

The high modulus aesthetic material exhibits unprecedented low mold shrinkage values (0 % md/0.1 % pmd) and is suitable for dimensionally stable metal replacement applications. The tensile strength of 265 MPa is high, and the processing window is relatively wide.

Mechanical values perpendicular to the fiber are 28-30 % better compared to competitor materials.

High performance polyamides of the same family with 40 % and 50 % glass fiber reinforcement are available.

50 % glass fiber reinforcement, aesthetic surface, low warpage

PX-DIPROmid A2H6.1G10T2U*9200 Product-ID: 734 Request data sheet

PA66 + X, 50 % glass fiber reinforcement, partially aromatic, low warpage, easy-flow, aesthetic surface

The influence of water absorption on the properties is low. This is a typical metal substitute material for the automotive industry and mechanical engineering.

PX-DIPROmid A2H6.1G10T3U*9200 Product-ID: 803 Request data sheet

PA66 + X, 50 % glass fiber reinforcement, partially aromatic, very low warpage, easy-flow, aesthetic surface

Compared to Product ID: 734, this high-performance material offers a wider processing window and less warpage.

DIPROmid T50.4H2C3*9200 and DIPROmid TR50.4H2*6000

Filament and component from Rheneon

With DIPROmid T50.4H2C3*9200, DIPRO®mat has developed a high-performance material with the following special features:

- amorphous polyamide with 15 % carbon fiber

- very high stiffness, tensile modulus = 10.400 MPa

- very high strength 160 MPa

- extremely low mold shrinkage of 0 – 0.1 %

- dimensionally accurate lightweight material

Filament and component from Rheneon

Another interesting material is DIPROmid TR50.4H2*6000 transparent.

- amorphous, transparent polyamide

- low warpage

- impact resistant and dimensionally stable

- can be dyed in brilliant colors as desired

The rheology of both products is matched to granulate and FFF printing.

- Information on our materials is available from ROTFELD-Consulting GmbH & Co. KG (uwe.stenglin@rotfeld-consulting.de).

- Information on filament and printability is available from Rheneon GmbH (sven.wohkittel@rheneon.com).

The DIPRO®mat team commissioned two highly specialized plants for thermoplastic AM materials (ETP and TPE) and also high-performance compounds for injection molding and extrusion in spring 2021. With a capacity of 1200 t/a, small quantities from 100 kg/batch as well as production quantities in the ton range can be produced for innovative partners.hergestellt werden.