Thermoplastics for Additive Manufacturing (AF)

Powder (SLS), Granulate (FGM), Filament (FFF)

High performance thermoplastics, radiation crosslinkable polymers

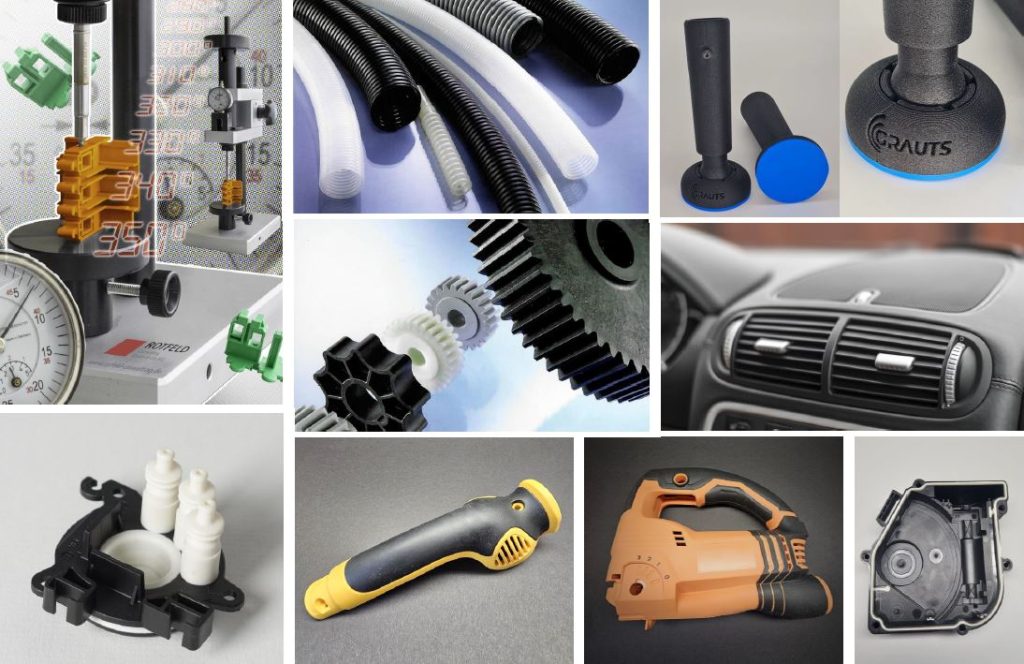

Thermoplastic elastomers for injection molding and extrusion

DIPRO®mat GmbH (Materials for Digital Production), founded in March 2020, focuses on the development and production of thermoplastic materials for Additive Manufacturing (AF).

Since a wide variety of 3D printing processes are already established on the market, DIPRO®mat will develop and produce thermoplastic materials in the form of filamentary pre-products as well as granulates and powder types.

The aim is to transfer the many years of experience of the main shareholder, Uwe Stenglin, in the application technology and development of thermoplastic injection molding materials. This should enable the use of well-known products such as PA (including high-temperature polyamides) or PP in the additive production.

DIPRO®mat thus closes the gap between the previous 3D standard materials, such as PA12, PLA, and ABS, which are easy to process but have moderate thermal properties, and ultra-high temperature materials, such as PEEK and PEKK, which are traded at very high prices.

In addition, the company plans to introduce the hard/soft combination into additive manufacturing, especially for 3D printing from filaments and granules.

The testing of new developments as well as the preparation of detailed technical data sheets is carried out in the in-house Plastics Engineering Center, which – like the production – has solid, high-quality equipment.

To round off the portfolio, our know-how in the development of special compounds for injection molding applications and extrusion is also available to you. We do not regard small quantities as a disruptive factor, but as part of our philosophy.

DIPRO®mat and ROTFELD-Consulting are driven by technical curiosity and imagination.